Littelfuse Arc Flash Relay Saves Plant from Catastrophic Damage

Littelfuse Arc Flash Relay Saves Plant from Catastrophic Damage

“Had this relay not been there, they were looking at between $800,000 to $1 million in damages…”

The Situation

A customer needed help to resolve and reduce a critical issue with an electrical hazard in their furnace control room. An earlier arc-flash analysis had determined that one 480-volt cabinet, which was fed from a 3500 kVA transformer, exceeded an arc-flash Hazard Risk Category 4 (HRC).

They knew that to be able to work on the cabinet or lower required PPE, they needed to find a way to lower the HRC.

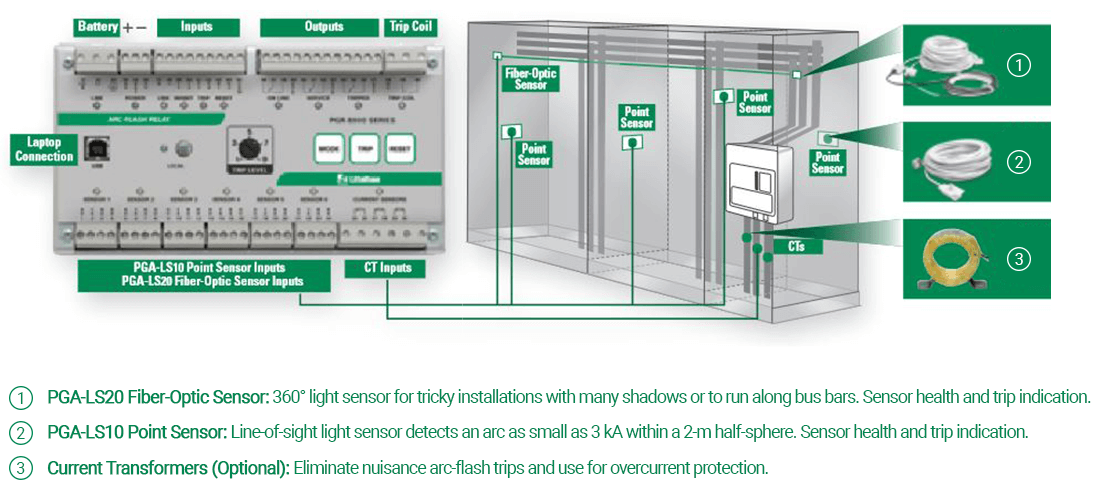

The PGR-8800 Arc-Flash Relay from Littelfuse was selected, which could be easily retrofitted into the existing cabinet. This device can lower incident energy by detecting a developing arc flash and sending a trip signal to the breaker within 1ms.

The Littelfuse PGR-8800 Arc Flash Relay was installed in the controls section of the cabinet, with two light sensors mounted in each of the three power compartments. The trip output of the relay was connected to the shunt trip input of the main breaker.

“It was a very easy installation compared to most relays”

The entire installation of the arc flash relay took only three hours, including mounting and testing the sensors.

After the relay was installed, an engineering firm rerated the cabinet's arc flash hazard from a Hazard Risk Category 4 to a Hazard Risk Category 2, a level easily approachable using 8cal/cm2 PPE.

The Arc Fault – Trial by Fire

The timing of this installation was incredibly fortunate. Over the years, sand used in the manufacturing process had accumulated around the cables in the pit below the cabinet; the cable insulation had become brittle as a result. It was just a matter of time before something happened, and only one week after the PGR-8800 was installed, the plant experienced an arc flash incident. Had the PGR-8800 relay not been there, this incident would have caused catastrophic damage to the facility and months of downtime.

It all started as a phase-to-ground fault in one of the cables below the cabinet. The arc tracked up the cable to the main bus inside the cabinet, where it threatened to escalate into a three-phase fault, drawing more energy and potentially destroying the cabinet, and the plant, not to mention the effect on any of the people who were usually nearby.

As the arc reached the cabinet, all six of the light sensors reacted to the bright arc-flash light, even the ones that didn’t have a direct line of sight. The Arc Flash Relay responded immediately, sending a trip signal to the main breaker in less than 1ms.

Without the PGR-8800, the main breaker would not have reacted fast enough to stop the catastrophic arc flash. Instead, damage was minimal: a thumb-sized piece of metal was burnt off one of the bus bars. The cabinet and the switchgear inside suffered only minor damage.

$1 Million Savings

Had this relay not been there, they were looking at between $800,000 and $1 million of cost, considering downtime and equipment replacement. Besides the lead-time for delivery and the installation, they would have had to cut a hole in the outside wall of the plant to install it. The estimated lead time on electrical equipment of that size, with 4000-amp capacity, would be anywhere from 10 to 24 weeks—and that’s just for delivery, not installation.

Summary

This is an example of how a minimal investment of just a few thousand dollars can save tremendous costs in lost equipment, downtime, and production, not to mention the risk of employee injury or fatality. This customer was fortunate with his timing, but a proactive strategy is recommended when it comes to protecting critical assets and employee safety. An arc-flash relay is an integral component of an arc-flash protection scheme that can minimize damage and save money, time, and lives.

Selecting the right relay

At Fuseco, we are the experts in helping select the best relay for ultimate protection of your assets.

The most important features of an Arc Flash relay are:

- Reaction Time

- Trip Reliability

- Ease of Installation

- Sensor Flexibility

- Software

- Sensor Design

- Avoidance of Nuisance Tripping

- Scalability

Not every system is the same, the Littelfuse range of Arc Flash Detectors understands this and has a flexible range, which can be easily retrofitted, to suit simple and complex systems.

Read the FAQ’s here

For more information on the key selection criteria: Key Considerations for selecting Arc Flash

For more information on the PGR-8800 Arc Flash Relay: PGR 8800 Series

To learn more about selecting the right Arc Flash Relay, simply contact us today.

We're here to help

Talk to an expert today.

Our friendly team of highly trained specialists will quickly assist you.

We promise to respond within 4 business hours (AEST).

Or you will receive $100 off your next purchase. Read how it works.

Top FAQs

A protection relay is a device that receives inputs typically from current transformers CT’s (but can be other sources) and then compares these inputs to set levels. If these inputs exceed the set levels a protection relay can then provide that information via display or indication, feed that information to other electronic control devices or it can be connected to a circuit breaker to isolate power.

Yes, currently Fuseco can offer both earth leakage and NER relays that are compliant to AS2081:2011. The relay manufacturer (Littelfuse) is also currently in the final stages of development for an AS2081:2011 compliant continuity relay that we expect to release in the near term.

An arc fault is a type of electrical fault that results from the breakdown of an insulating medium between two conductors where the energy is enough to sustain an arc across the insulator (often air) and can cause extreme amounts of light (arc flash), immense heat upwards of 19,000 degrees, and a resulting explosive pressure wave (arc blast). By using a relay that has optical sensors we can detect the flash of light the emanates from an Arc Flash and within 1 msec send a signal to a breaker to interrupt power. Because of the immense energy being released by an Arc Flash reaction time is critical. It can be seen on the graph that with a relay reaction time of only 1 msec (+ circuit breaker reaction time) we can interrupt power before the Arc Flash can result in critical damage.

An arc-flash happens when electric current flows through an air gap between conductors. There are several ways this can happen but the most common occurrence is when conductor insulation is worn or broken down.

The most important aspects of arc-flash relays are:

- reaction time

- trip reliability

- ease of installation

- sensor flexibility

- software

- sensor design

- avoidance of nuisance tripping

- scalability

To gain a deeper understanding of which features to consider when selecting an arc-flash relay please refer to the downloadable application guides.

Arc-flash relays are a necessary component in an electrical cabinet because they reduce the amount of incident energy in the system. While an arc-flash relay cannot prevent an arc flash from happening, it will protect critical assets and workers’ safety by reducing the severity of the flash. An arc-flash relay is an integral part of an arc-flash protection scheme that can minimize damage, and save money, time, and lives.

Three phase power systems are most often solidly earthed, however by using a Neutral Earthing Resistor (NER) a power system can be resistance earthed. This is done so that if an earth fault were to occur the amount of fault current will be limited by the NER resistance. One potential problem with a resistance earthed system is; what happens if the NER goes open circuit due to damage? If this were to happen the power system has now changed from a resistance earthed system to a system with no earth reference (floating). Now the NER is no longer restricting the amount of fault current and other devices that rely on an earth reference in order to operate, cannot do so. By using a NER monitoring relay the resistance and integrity of a NER can be continually monitored to detect for any variance in the NER resistance or integrity.

An earth fault can occur as a result of inadvertent contact between and energized conductor and earth or equipment frame. There can also be earth leakage from a system without “inadvertent contact”. This type of fault can be called capacitive earth leakage and it is caused by a capacitive effect between a high power conductor and earth. Small amount of earth leakage current can occur as a result of this capacitive effect. Whether it is smaller amounts current from capacitive earth leakage or larger amounts of current from direct inadvertent contact an earth leakage relay can detect this fault current. In all electrical circuits, current returns to its source. An earth fault relay can use a zero sequence CT to monitor phase current to ensure that all current coming from the source returns on those same conductors or it can monitor current in the connection between transformer neutral and earth. By either method the earth leakage relay detect any lost current to earth.

Hi Tim, just wanted to thank you and the Fuseco team for your help. You've managed to help us solve some nagging issues here and the Littelfuse SE-330AU relay installation has saved us a lot of time. Thanks!

Mark Sherman

PGS Silver, Queensland

Just wanted to send a note of thanks to you guys. When it comes to relays, your advice & service is high level & appreciated. Cheers.

Jesse Marshall

Newcrest WA

The Littelfuse SE-701 & the CT's are functioning well. Thanks guys, really appreciate your help. Good to work with people you can rely on.

Cliff Peligro

Alpha Coal, Queensland

Technical Support

Our experts are all pre-eminent leaders in electrical products who provide excellent support in their areas of expertise.

Technical supportTalk to an expert

Our friendly team are highly trained product experts who really enjoy helping customers find what they need.

call 1300 387 326Enquire by email

We promise to respond within 4 business hours (AEST) or you will receive $100 off your next purchase.

Enquire now